Introduction

The modern battery maintenance industry demands sophisticated charging solutions that go beyond basic power restoration. Professional automotive workshops, marine service centers, and industrial maintenance facilities require equipment that not only charges batteries efficiently but also extends their operational lifespan through advanced repair technologies. The 12V10A Intelligent Pulse Repair Multifunctional Charger with Integrated Lamp for Lead Acid Battery represents a breakthrough in intelligent charging technology, combining pulse repair capabilities with integrated illumination for enhanced workshop functionality.

This advanced charging solution addresses the critical need for battery maintenance equipment that can detect, analyze, and repair sulfation damage while providing reliable charging performance. By incorporating intelligent pulse technology with multifunctional design elements, this charger serves as an essential tool for professionals who demand precision, reliability, and versatility in their battery maintenance operations.

Product Overview

The intelligent pulse repair charger represents a sophisticated approach to lead acid battery maintenance, integrating cutting-edge pulse technology with practical workshop functionality. This multifunctional device combines traditional charging capabilities with advanced pulse repair algorithms designed to break down sulfate crystals that commonly form on battery plates over time. The integrated lamp feature adds practical value by providing illumination during maintenance operations, making it particularly useful in dimly lit workshop environments or outdoor service locations.

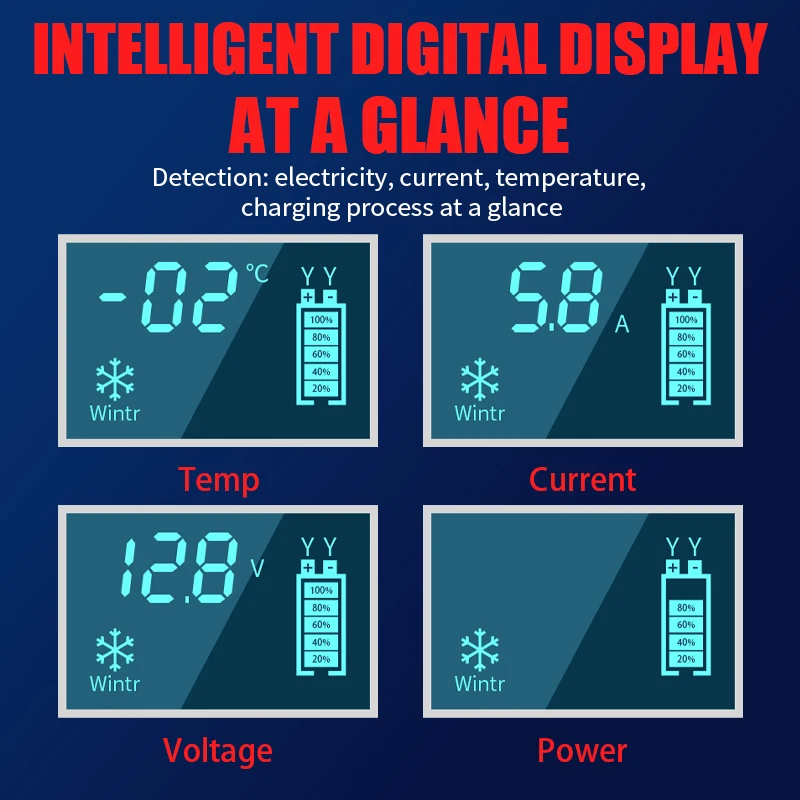

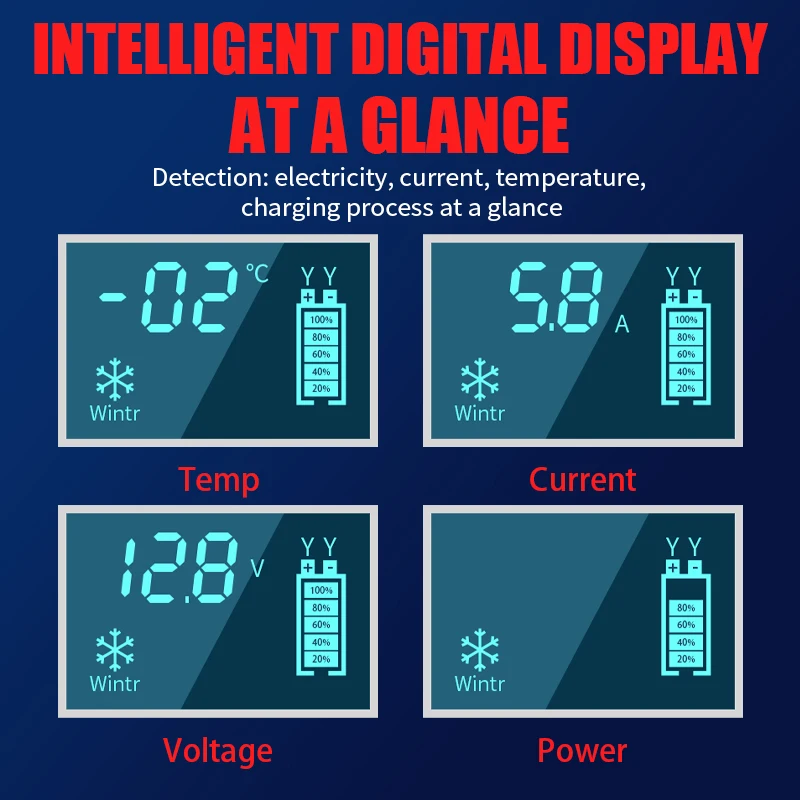

Built specifically for lead acid battery applications, this charger incorporates microprocessor-controlled charging cycles that automatically adjust parameters based on battery condition and type. The intelligent system continuously monitors voltage, current, and temperature parameters to ensure optimal charging performance while preventing overcharging or thermal damage. The pulse repair functionality works by delivering controlled high-frequency pulses that help dissolve sulfate buildup, potentially restoring capacity to batteries that might otherwise be considered beyond repair.

The multifunctional design extends beyond basic charging to include diagnostic capabilities, maintenance modes, and user-friendly interface elements that make professional battery care accessible to technicians of varying experience levels. The integrated construction ensures reliable operation in demanding workshop environments while maintaining compact form factor for convenient storage and portability.

Features & Benefits

Intelligent Pulse Repair Technology

The core innovation of this charging system lies in its sophisticated pulse repair technology, which addresses one of the most common causes of lead acid battery failure. Sulfation occurs when lead sulfate crystals accumulate on battery plates, reducing capacity and performance over time. The intelligent pulse system generates precisely controlled high-frequency pulses that help break down these crystals, potentially restoring significant capacity to batteries that have experienced sulfation damage.

This pulse repair functionality operates automatically during charging cycles, continuously monitoring battery response and adjusting pulse parameters for optimal effectiveness. The microprocessor-controlled system ensures that pulse therapy is applied safely without risking damage to healthy battery cells, making it suitable for both preventive maintenance and corrective repair applications.

Multifunctional Charging Capabilities

Beyond pulse repair, this charger offers comprehensive charging functionality designed to accommodate various lead acid battery types and applications. The intelligent charging algorithm automatically detects battery condition and selects appropriate charging parameters, eliminating guesswork and reducing the risk of user error. Multiple charging modes accommodate different battery chemistries within the lead acid family, including flooded, AGM, and gel cell variants.

The system incorporates advanced safety features including reverse polarity protection, short circuit protection, and thermal monitoring to ensure safe operation in professional environments. Automatic shut-off capabilities prevent overcharging while maintaining optimal battery condition through intelligent maintenance modes that can be left connected for extended periods.

Integrated Lamp Functionality

The built-in illumination system adds significant practical value to workshop operations, providing focused lighting exactly where needed during battery maintenance procedures. This integrated approach eliminates the need for separate work lights and ensures that technicians have adequate visibility for connection procedures, battery inspection, and diagnostic activities. The lamp system is designed for durability and energy efficiency, contributing to overall workshop productivity without imposing significant power demands.

The strategic placement of the integrated lamp ensures optimal illumination angles for typical battery maintenance scenarios, while robust construction ensures reliable operation in challenging workshop environments. This feature proves particularly valuable for mobile service applications where external lighting may be limited or unavailable.

Applications & Use Cases

Professional automotive service centers represent a primary application area for this intelligent charging system, where battery maintenance and repair services generate significant revenue opportunities. The pulse repair capability allows service centers to offer battery restoration services as an alternative to replacement, potentially extending battery life and providing added value to customers. The integrated lamp facilitates efficient service bay operations, particularly during evening hours or in poorly lit service areas.

Marine service facilities benefit significantly from the advanced charging capabilities, as marine batteries often experience challenging operating conditions that accelerate sulfation and capacity loss. The intelligent charging algorithms accommodate the specific requirements of marine deep-cycle batteries, while the pulse repair function helps maintain optimal performance in batteries subjected to frequent discharge cycles. The integrated illumination proves particularly valuable for marina service operations where natural lighting may be insufficient.

Industrial maintenance departments utilize this charging system for maintaining backup batteries, emergency lighting systems, and portable equipment power sources. The multifunctional design allows maintenance teams to standardize on a single charging solution for various lead acid battery applications throughout their facilities. The pulse repair capability helps extend the service life of critical backup batteries, reducing replacement costs and improving system reliability.

Fleet maintenance operations benefit from the efficiency and versatility of this charging system, particularly for maintaining auxiliary batteries in commercial vehicles, emergency equipment, and support vehicles. The intelligent charging algorithms ensure optimal battery condition across diverse vehicle types, while the pulse repair function helps maximize battery investment returns through extended service life.

Quality Control & Compliance

Manufacturing excellence forms the foundation of this intelligent charging system, with comprehensive quality control processes ensuring consistent performance and reliability across production batches. Advanced testing protocols validate charging accuracy, pulse repair effectiveness, and safety system functionality before units leave the manufacturing facility. Environmental testing confirms reliable operation across typical workshop temperature and humidity ranges, ensuring dependable performance in real-world applications.

The charging system meets relevant international safety standards for battery charging equipment, incorporating multiple protection systems and fail-safe mechanisms to prevent damage to connected batteries or surrounding equipment. Electromagnetic compatibility testing ensures that the pulse repair system operates without interfering with other electronic equipment commonly found in professional workshop environments.

Component selection emphasizes long-term reliability and performance consistency, with critical electronic components sourced from established suppliers with proven track records for quality and reliability. The integrated lamp system undergoes separate testing protocols to ensure optimal light output and extended operational life under typical workshop conditions.

Continuous improvement processes incorporate feedback from professional users to refine charging algorithms, enhance safety systems, and optimize user interface elements. This ongoing development ensures that the charging system continues to meet evolving industry requirements and maintains compatibility with new battery technologies as they emerge in the marketplace.

Customization & Branding Options

Professional distributors and importers can access comprehensive customization services to align this intelligent charging system with their specific market requirements and branding strategies. Custom packaging solutions accommodate different regional preferences and distribution channels, while maintaining product protection and presentation quality. Graphics customization allows integration of distributor branding, technical specifications, and regional compliance information.

The charging system housing can accommodate custom color schemes and branding elements to match distributor product lines or specific market preferences. This flexibility enables distributors to differentiate their offerings while maintaining the core technological advantages of the intelligent pulse repair system. Custom documentation packages support localization requirements, including translated user manuals, technical specifications, and safety information.

Private labeling options provide opportunities for distributors to establish their own branded charging solutions while leveraging proven technology and manufacturing excellence. These programs include comprehensive support for product registration, warranty administration, and technical support coordination to ensure seamless market introduction and ongoing customer satisfaction.

Accessory customization allows distributors to configure complete charging solutions that meet specific market requirements, including custom cable lengths, connector types, and carrying cases. This flexibility ensures optimal market fit while maintaining manufacturing efficiency and cost effectiveness.

Packaging & Logistics Support

Comprehensive packaging solutions protect the intelligent charging system throughout international shipping and distribution processes while optimizing logistics efficiency. Multi-layer protection systems safeguard sensitive electronic components from impact, moisture, and temperature variations commonly encountered during global transportation. Packaging design considerations balance protection requirements with dimensional efficiency to minimize shipping costs and maximize container utilization.

Modular packaging approaches accommodate different order quantities and distribution strategies, from individual retail units to bulk distributor shipments. This flexibility supports various business models while maintaining consistent product protection and presentation quality. Sustainable packaging materials align with environmental responsibility objectives while ensuring adequate protection for sophisticated electronic components.

Documentation packaging integrates user manuals, warranty information, and technical specifications in weather-resistant formats that maintain readability throughout the distribution chain. Multi-language documentation options support international distribution requirements while ensuring that end users receive complete product information in their preferred language.

Logistics coordination services assist international distributors with shipping optimization, customs documentation, and delivery scheduling to minimize lead times and ensure predictable inventory replenishment. These services prove particularly valuable for distributors managing multiple product lines and complex international supply chains.

Why Choose Us

Our company brings extensive experience in developing advanced battery charging solutions for professional markets worldwide, with established relationships spanning automotive, marine, and industrial sectors across multiple continents. This global perspective ensures that our products meet diverse market requirements while maintaining consistent quality and performance standards that professional users demand.

As a recognized metal packaging manufacturer and technology developer, we understand the importance of robust construction and reliable performance in demanding professional environments. Our multidisciplinary expertise encompasses both electronic system design and durable enclosure engineering, ensuring that products deliver long-term value in real-world applications. This integrated approach distinguishes our solutions from competitors who may excel in single disciplines but lack comprehensive system optimization capabilities.

International collaboration with distributors, service centers, and equipment manufacturers provides continuous feedback that drives product improvement and innovation. This market connectivity ensures that our charging solutions evolve with changing industry requirements and incorporate emerging technologies that enhance user value and competitive advantage.

Our commitment to professional markets extends beyond product development to include comprehensive support services that help distributors succeed in their local markets. Technical training programs, marketing support materials, and ongoing product development communication ensure that distributor partners have the resources needed to effectively promote and support advanced charging solutions.

Conclusion

The 12V10A Intelligent Pulse Repair Multifunctional Charger with Integrated Lamp for Lead Acid Battery represents a significant advancement in professional battery maintenance technology, combining intelligent charging algorithms with innovative pulse repair capabilities and practical integrated illumination. This comprehensive solution addresses the evolving needs of professional service providers who require equipment that not only charges batteries efficiently but also extends their operational lifespan through advanced repair technologies.

The integration of multiple functional elements into a single, robust platform provides exceptional value for professional users while simplifying equipment selection and inventory management. From automotive service centers to marine facilities and industrial maintenance departments, this intelligent charging system delivers the reliability, versatility, and performance that professional applications demand. The combination of advanced technology, practical functionality, and comprehensive support services ensures that this charging solution continues to deliver value throughout its operational life, making it an essential tool for any professional battery maintenance operation.

| Model | 12v10A |

| Input voltage | AC110-240V;50/60HZ |

| Output voltage | 12-15.5V |

| Output current | 10A |

| Shell materia | ABS flame retardant alloy plastic |

| Product size | single package is 22.5X12.5X6.5CM, and the size of the full box is 62.5X48.5X35.5CM |

| Product weight | the we ight of the single package is 450G, and the weight of the full container is 27KG |

| Power line length | Conventiona 80X80CM(Length can be customized) |

| product function | Microcomputer smar t chip, soft start, temperature control protection shortcircuitprotection,over voltageandovervoltageprotection,reverseprotection |